Mixing up brake pads on a race car can seem counterintuitive at first glance but NASCAR Cup teams often do it on purpose in order to work around the rules and anyone wanting to be competitive at Phoenix this weekend will be trying it.

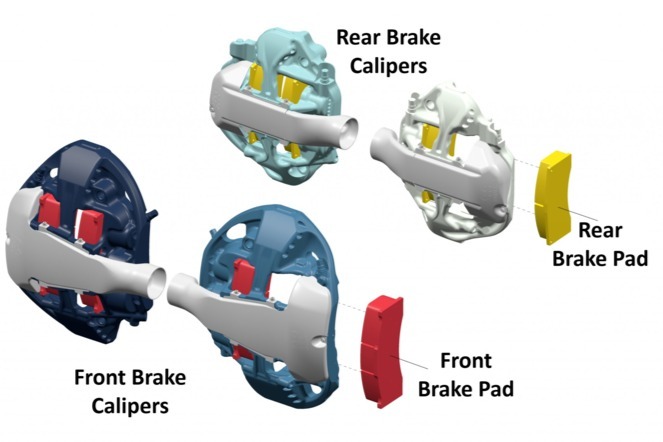

The NASCAR Next Gen car is mostly assembled with single source parts so teams can’t build custom suspension or brake components but brake pad compounds are not limited so teams have figured out how to alter the handling of the car by mixing friction compounds and installing different types of brake pads on each corner of the car.

This practice is known as splitting brake pads and it can be very effective at making a race car faster or more stable into a turn but can also be dangerous as the imbalance of friction from side to side can overheat the brakes and cause a rotor to shatter as we saw with the No. 20 of Christopher Bell at the 2023 NASCAR championship race at Phoenix.

How brake pad splitting works

Crew working inside wheel wells of Austin Cindric’s Team Penske Ford

Photo by: David Buono – Icon Sportswire – Getty Images

In the simplest terms, brake pad splitting means that you have a split compound either side to side or front to rear where the brake pads across any angle are not matched but instead have different friction compounds. In an environment where teams cannot build custom suspension or brake components in order to improve the handling of the car they chase whatever part is open and having higher friction pads on the right side of the car can help a car be more stable entering a corner.

We checked in with Joey Cohen who is currently president of GMS Race Cars and has worked in a wide range of technical positions in NASCAR and other series ranging from engineer to executive to learn more about brake splitting and why Cup teams split brake pads.

“This is done in an effort to tune for balance based on how braking torques are applied,” Cohen explained. “This can help how a car loads a certain corner under braking along with weight transition and also the temperature range the brake can operate at. Some common configurations could be front v. rear, left v. right, or even isolated to one corner of the vehicle to prevent lock-ups when a wheel becomes light on load.”

Why brake pad splitting is important at Phoenix

As Cohen shares, the brake pads end up being used to force the car to turn a certain way with specifically chosen corners of the car being grabbier than others and it becomes significantly important at a track like Phoenix Raceway because of its unique layout. Phoenix is an asymmetric track so braking and handling of every corner is unique and setting up the car is always a compromise but splitting the pads can mitigate some of that. Entry into turn 1 at Phoenix compared to turn 3 is quite different due to the layout of the track and Cohen shares that “Into turn 1, your entry is coming off the dogleg front straightaway while the entry into turn 3 is more completed in a straight line off the back stretch.”

The split brake pads act almost like a customized suspension in order to allow handling to be equalized across unique corners in conjunction with the brake bias adjustment that the drivers have in the car which allows them to shift brake pressure from front to rear on the fly.

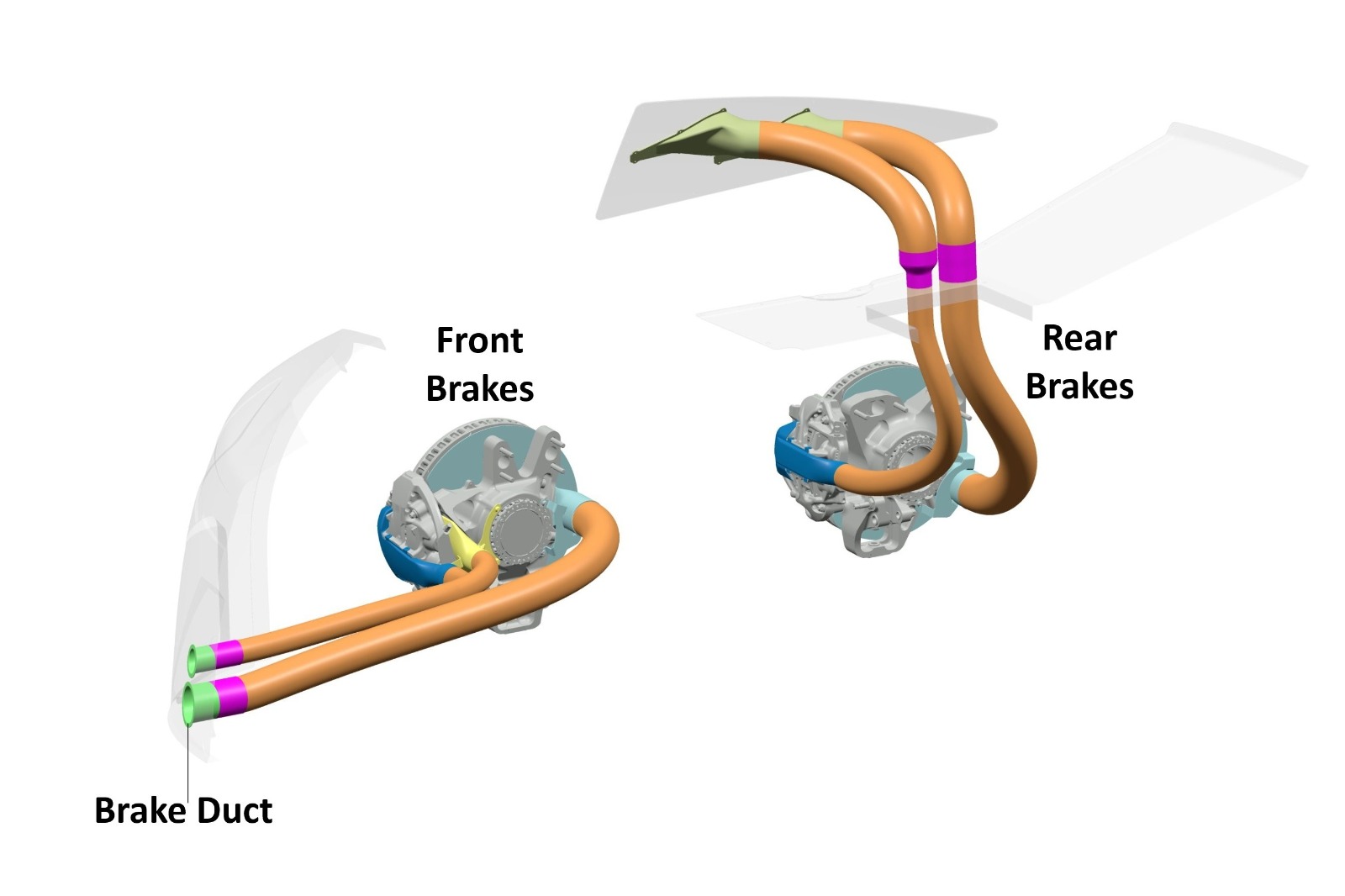

Another one of the unique aspects of Phoenix that isn’t present at other short tracks is the fact that it has pretty long straightaways which means that the brakes can see large temperature swings if the brake ducts are wide open. In certain cases, teams will adjust the friction compound of a certain corner of the car in order to minimize those temperature swings if they expect the corner to be overcooled on the straights.

Aero also plays a much larger role at Phoenix than at other short tracks and Cohen mentions that splitting brake pads can also mitigate certain aero effects: “Braking can create large variations in platform of the vehicle (pitch movement forward). This will affect the overall and front/rear downforce profile of the race car transitioning from entry to center of the corner. A brake pad of varying friction configuration can eliminate or smooth out the platform variations.”

Why teams use brake pad splitting

A detailed view of the NASCAR Next Gen wheel

Photo by: James Gilbert / Getty Images

In past generations of the NASCAR Cup car, teams could build custom suspension components and select very specific brake components for the car based on track and even mix and match things like brake calipers or suspension arms from corner to corner. The Next Gen model eliminated all of those choices so teams now must use spec parts from specific suppliers when building cars and the same brake calipers and suspension arms must be used across a variety of different tracks.

In addition to having the ability to build custom brake and suspension components in past generations, teams could also install shut off or delay valves or route brake lines in specific configurations in order to affect the bias to any specific corner of the brakes. Cooling was also up to the teams so they could match specific corners with custom cooling for the friction profile of the brakes or for specific aero that they might be chasing. With all of these options off the table, teams now try to do all of those changes solely by customizing the friction compounds of the brake pads.

How brake pad Splitting can be dangerous

Christopher Bell, Joe Gibbs Racing Toyota

Photo by: Jared C. Tilton/Getty Images

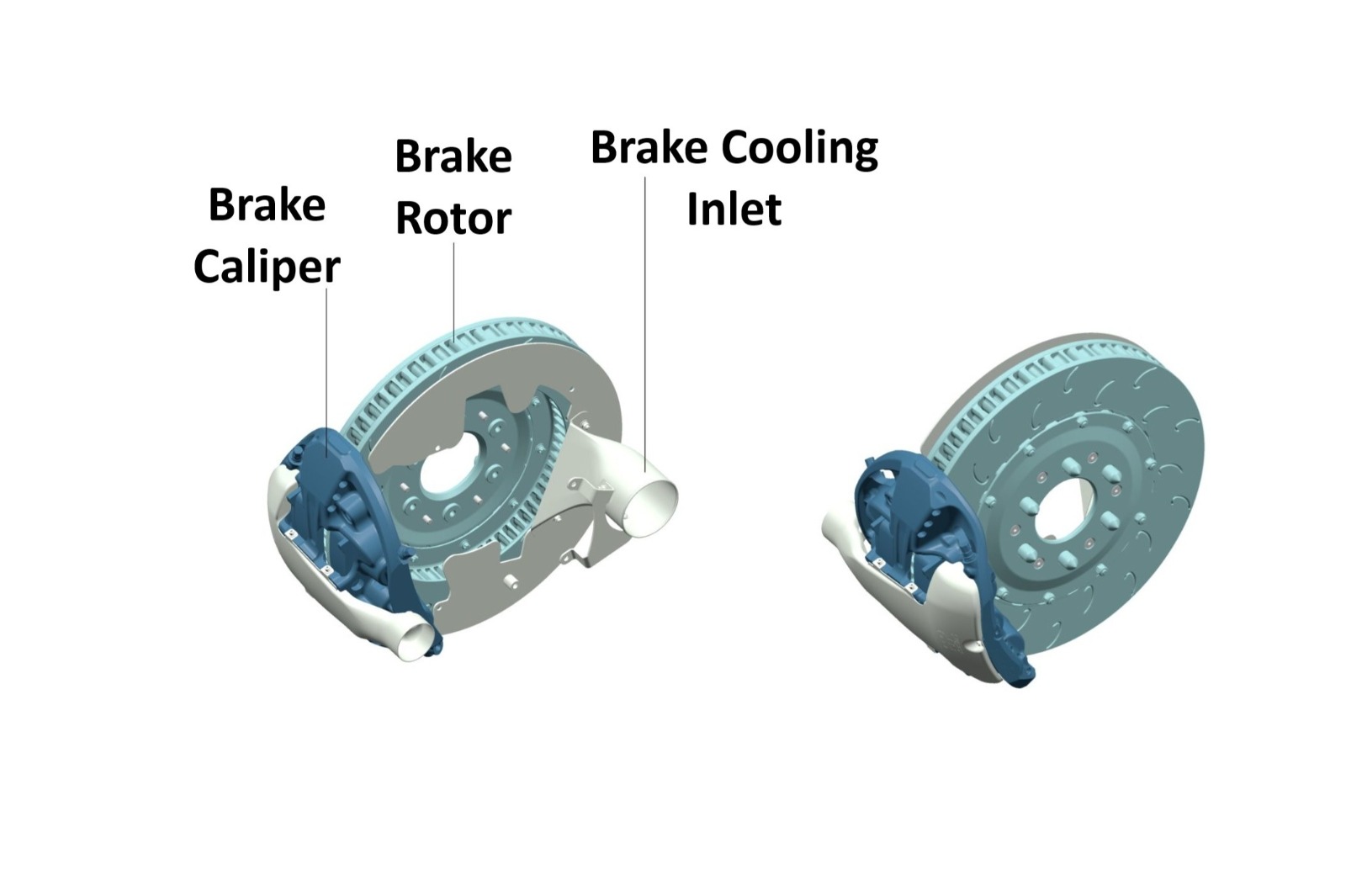

We saw the championship hopes for Bell end quickly during that 2023 finale at Phoenix as his right front rotor shattered and took the right front wheel and tire. This is where the dangers of brake pad splitting come in and why it’s always a delicate balance when teams chase performance in unorthodox ways. The likely scenario in that situation is that they were chasing stability while entering a corner by having higher friction pads on the right side of the car versus the left. It worked for a while but they went too far as the heat generated by the friction on the right front was too much for the available cooling.

Once the rotor gets too hot it can grow to such an extent that it can contact the brake caliper and then once the car gets on a straightaway it will be suddenly cooled off which can cause it to shatter from the large temperature difference. Cohen notes that there are a variety of other disadvantages of splitting pads especially over a long run in a race.

“High temperature pad compounds can hold residual heat that could cause rotor cracking, glazing of the rotor surface (less available friction), and failure in caliper seals and components which would lead to total corner failures of the braking system,” said Cohen. “Uneven rotor wear and tapering of an individual corner can create vibrations and wheel shake for the driver under braking, and inconsistency in the response of the brake pedal.”

Teams will have some tough choices to make once practice wraps up at Phoenix as they decide which brake pads they want to take into the race and how big of a risk they want to take with championship hopes on the lines.

We want your opinion!

What would you like to see on Motorsport.com?

– The Motorsport.com Team