Question: What could be better than having one set of 3D-printed irons in your lineup?

Answer: Why, three sets of 3D-printed irons, of course.

COBRA is clearly all-in on 3D-printing technology. By adding two new iron sets to complement last year’s marvelous 3DP Tour, COBRA feels it can fit anyone from a tour-level ball striker to a 25 or higher handicapper.

With three iron sets.

I don’t care who you are, that’s pretty impressive.

If, of course, they can pull it off.

That said, let’s get this Launch Party started with a closer look at the new COBRA 3DP MB and 3DP X irons. We think COBRA might be on to something.

Why does COBRA 3D print irons?

3D printing isn’t new in golf. COBRA and others have been 3D printing playable prototypes for years. However, COBRA is the first – and still only – OEM to commercialize the technology. It started in 2020 with a 3D-printed putter. In 2024, COBRA proved the iron concept with two rounds of the limited-edition LIMIT3D irons. Those irons morphed into last year’s 3DP Tour. That iron had a blade-like footprint but with game-improvement-level forgiveness and playability.

(Yes, we know AVODA made 3D-printed irons for Bryson. Those, however, were a one-off and were 3D-printed because it was the quickest way to get Bryson a playable set of his curved-face irons in time for the 2024 Masters. AVODA does not offer 3D-printed irons for sale and, as far as we know, has no plans to.)

“3D printing allows us as designers and product creators to do things we couldn’t do with normal forging or casting,” COBRA Innovation Director Ryan Roach tells MyGolfSpy. “It’s changed our way of thinking as to what’s possible.”

By adding a 3D-printed muscle-back and player’s distance iron, COBRA believes it has the horses to bring 3DP technology to tour players, 25 handicappers and everyone in between.

“It depends on a golfer’s needs,” says Roach. “But in talking with our fitters, they say that with these three models, they can fit anybody.”

Before we proceed, we need to understand what 3D printing enables COBRA to create. The iron itself doesn’t magically hit the ball better or farther. What 3D printing does is allow COBRA to separate form from function.

“That separation allows us to get more forgiveness into an iron without sacrificing shape or impact feel to get there,” explains Roach. “We can affect CG (center of gravity) and MOI (moment of inertia) without having to change the head shape.”

Form, function and forgiveness

With traditional forgings or castings, form follows function. For an iron to have game-improvement-level forgiveness, the chassis must be large enough to accommodate a super-low center of gravity and provide sufficient MOI for stability. There’s a reason, after all, why game-improvement irons look the way they do.

“With 3D printing, we’re actually changing the internal form to get the function we want,” says Roach. “The outer form is something we can control separately.

“We can hone in on the feel we want and the shape we want and then put in the forgiveness that a player needs in a given category.”

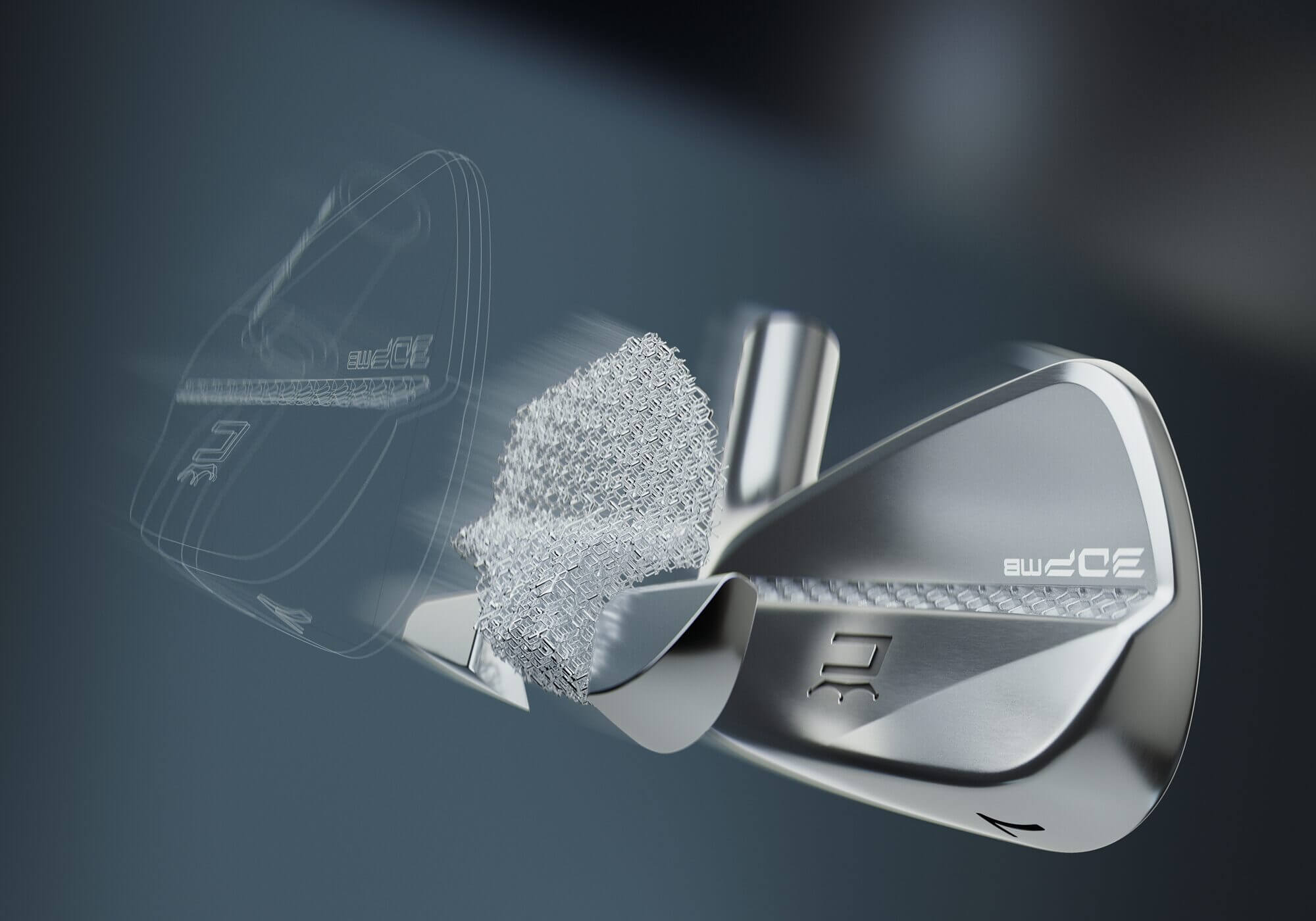

3D printing allows COBRA to create an interior that’s virtually impossible to make with traditional manufacturing. The secret sauce is a unique internal lattice structure that frees up an ungodly amount of discretionary weight for such a small footprint.

For example, the new 3DP MB muscle-back features a thinner topline than COBRA’s forged KING MB, with an overall chassis that’s smaller than the forged KING Tour. The internal lattice structure, however, frees up 66 grams of discretionary weight. That allows COBRA to move 35 grams of tungsten weighting to the toe, 23 grams to the heel and eight grams into the hosel to increase forgiveness and lower the CG.

For an iron that size, 66 grams is significant.

“We could have dropped the CG lower with the MB, but we chose not to,” Roach explains. “MB players typically don’t have a problem launching the ball. They do want that extra forgiveness along with adequate spin, however, so we were mindful not to drop the CG too low.”

The 3DP X, being more of a player’s distance iron, is all about getting the CG low for high launch and low spin.

COBRA 3DP MB and 3DP X specifics

The COBRA 3DP MB is based on the prototype 3D-printed muscle-back (a single piece without the lattice) that it made for Max Homa. The 3DP MB is also a single-piece blade but the internal lattice allows it to achieve the forgiveness of COBRA’s KING Tec X game-improvement iron.

As mentioned, the topline is slightly thinner than COBRA’s forged KING MB blade but has a touch more offset. The loft structure is what you’d consider traditional, with a 34-degree 7-iron.

“It has player-preferred shaping and feel,” says Roach. “But it’s playable for up to a 10 handicap, depending on why you’re a 10.”

Last year’s 3DP Tour also has a head shape smaller than the KING Tour but with even more discretionary weight and a lower CG, it has the forgiveness of a game-improvement iron. Which makes one wonder, why did COBRA give us a 3DP X?

“Although the 3DP Tour is very forgiving, higher handicaps might like to have a little bit bigger face,” says Roach.

The 3DP X is about the same size and shape as the KING Tec-X but COBRA says it’s even more forgiving than the DS-ADAPT Max super game-improvement iron.

Loftwise, the COBRA 3DP X, with a 29-degree 7-iron, is two degrees weaker than the KING Tec-X. As a result, the 3DP X delivers a little less ball speed and carry distance. The launch angle is higher and the spin is about 800 rpm higher compared to the KING Tec-X in player testing.

“The 3DP X gives more launch, a steeper descent and more playable distance,” says Roach, “but with much better feel.”

About that feel …

We like to equate forged construction with a soft, buttery feel. And while forging and materials play a role, geometry plays an even bigger one.

“It’s very much shape-dependent,” Roach explains. “If you had a forged muscle-back and a cast muscle-back, it would be surprising how few of us could tell the difference.”

COBRA’s 3DP irons are, of course, 3D printed using a 316 stainless steel powder that’s the consistency of powdered sugar. A single metal jet printer (the same as used in aerospace manufacturing) can print up to 32 heads over 24 hours. COBRA’s design software not only allows them to fine-tune the lattice structure but also lets them define impact sound and impact vibration.

“The feel isn’t exactly the same as a traditional forging,” says Roach. “Some people say it feels better, others say it’s not quite the same.”

My own experience last year with the 3DP Tour irons bears that out. It wasn’t a traditional forged sound and feel. I wouldn’t categorize it as better or worse, just different on a similar level. Overall, I found it pleasing.

What the lattice does do is that whether you’re talking the 3DP MB, Tour or X, the sound and feel will be in line with a forged muscle-back.

“The key is the lattice network printed into the clubhead during the printing process,” Roach says. “Without 3D printing, you couldn’t get the performance we’re seeing with the feel we’re getting.”

Do we really need 3D-printed irons?

The short answer is no. We didn’t need a perimeter-weighted putter, either, but that didn’t stop Karsten Solheim. Did we need a forged cavity-back? Nope, but Hogan created the Edge anyway.

We’ll say it again so there’s no misunderstanding. A club like the COBRA DS-ADAPT Max gives you the same forgiveness, distance and, likely, overall performance as the 3DP X. There’s no magic in 3D printing other than you can get all that forgiveness and performance in a much smaller chassis with much better feel. Disrupting the status quo, rewriting the rules and opening up new possibilities can’t possibly be a bad thing.

“There are 14 clubs in a golfer’s bag. We think there’s a place for 3D printing in every one of them,” says Roach. “It may not happen tomorrow but that’s our vision for where this will go.”

COBRA is confident that anyone from a tour player to a 25 handicap will find happiness with one of its 3D-printed irons. Down the road, however, 3D printing could change club fitting as we know it. Imagine your club-by-club specs turned into ones and zeroes. A 3D printer whirrs into action and, in a matter of hours, you have a set of clubs 3D printed to your exact and specific needs.

Talk about bespoke.

“That’s closer than it was five years ago,” says Roach. “We’re doing that now for tour players. The writing on the wall says that’s something we can eventually get out to consumers. We just don’t know when.”

COBRA 3DP MB and 3DP X specs, price and availability

Here’s some news that should make you southpaws happy. Thanks to 3D printing, the 3DP MB and 3DP X irons will be available in left- and right-handed models.

The COBRA 3DP MB will come stock with the KBS $-Taper 110 as the stock shaft. The 3DP X comes stock with the KBS Tour Lite. Both will feature the Lamkin Crossline as the stock grip. Both will have 4-irons and gap wedges available through custom order and the MB will offer a 3-iron as well.

As with the 3DP Tour irons, the new iron sets won’t be what you call “bargain-basement.” Each will cost $1,980 for a six-piece set.

They’re available for pre-sale starting today. They hit the stores on Jan. 9.

The post Why COBRA Is Doubling Down On 3D-Printed Irons appeared first on MyGolfSpy.