Seriously, when was the last time you actually thought about a Mizuno driver? Had the Red Sox broken the Curse of the Bambino yet?

Yeah, it’s been a while.

The good news is that today just might be the day you’ll want to start paying attention. You’re going to hear a ton of new tech stories in the coming weeks, but the new Mizuno JPX One drivers might have the most fascinating.

The problem is that it’s not something gimmicky that can be told in a quick catchphrase. There are two reasons for that.

The first is that to really understand – and convey to you – why these drivers are so compelling, we’ll have to get kinda tech-wonky. The story requires background, context and an understanding of polymers that can be measured on a scale that goes down to one-billionth of a meter.

The second is that a gimmicky catchphrase just isn’t Mizuno’s style. Never has been.

How this tech plays out and whether Mizuno can finally grab a seat at the 2026 Driver Head Table remains to be seen. It will, however, be one of the most interesting stories you’ll read today. So strap yourselves in, science geeks. We’re about to embark on a journey through time, space and the world of Nanoalloy.

Mizuno JPX One: The back story

No one thinks of Mizuno as an innovative driver company, for good reason. For the last 15 years or so, it hasn’t been.

That wasn’t always the case. For instance, did you know Mizuno came out with the world’s first pure titanium driver? That would be the Ti-110 in 1990. It also introduced the first carbon crown on a titanium metalwood in 2004, the MP-001. Four years later, the MP600 launched a new wave of adjustability with the first-ever sliding weight track system.

Since 2010, Mizuno has released some nice drivers that, for one reason or another, got lost in the annual metalwood cattle call. To reverse that trend, Mizuno did what any modern OEM would do.

It commissioned a study.

“We wanted to learn more about how to better service the metalwoods market,” Mizuno USA Director of Golf Chris Voshall tells MyGolfSpy. “We wanted to put down on paper what we already knew.”

Specifically, Mizuno learned three important things. First, it needed to enhance its metalwood fitting support to its retailers and fitters. Second, it needed to focus on innovation with visible technology. Mizuno will never be the loudest storyteller out there so it needs to grab your attention somehow.

Finally, to kickstart its efforts, it would need to get aggressive with its pricing. The Mizuno ST-230 family was introduced in 2023 and expanded a year later. In mid-2024, Mizuno turned the clock back to 2007 and priced the ST-230 line at $299.

Crazy, right?

“You ask any retailer what we would need to do to sell a Mizuno wood, they’d invariably say, ‘Make it cheaper,’” says Voshall. “We were literally losing money on some of the woods we were selling, especially when the tariffs went up.”

Did it work?

Normally, OEM driver sales can drop up to 70 percent in a product’s second year. That’s expected. However, Mizuno actually sold six times more ST drivers in 2025 than in 2024.

Aggressive pricing certainly helped but aggressive pricing doesn’t save a crappy product. Mizuno felt its ST drivers were pretty good and the additional fitting support helped consumers see that as well.

“For us to put a third-year product in a fitting cart was a significant investment,” Voshall admits. “Financially, it’s kind of idiotic but the idea was to get retailers comfortable fitting our product.”

Mizuno spent the better part of the past five years improving ball speed and forgiveness to at least be on par with market leaders. The final piece was creating an innovative, meaningful and, more importantly, visible technology to grab your attention.

We’ve said in this space before that while the USGA has speed regulations in place, there’s still room for improvement in driver technology and performance. Those improvements won’t be huge but they are real. That understanding led Mizuno to ask a fascinating question.

“We know what a titanium face does and we know what a carbon face does,” explains Voshall. “On the golf ball side, there are urethane and ionomer covers. We know what happens when those two things collide. We’re all playing from the same playbook.

“What could we do to change the interaction between ball and driver? How do we break that known condition that happens when these two things collide?”

That simple question led to a strange robotic test and, ultimately, to Nanoalloy.

This, friends, is going to get wonky.

Nanoalloy and the need for speed

“When a driver hits a ball, we know exactly what it means in terms of ball speed,” says Voshall. “Can we put something in between a titanium driver face and a urethane golf ball to make that interaction change?”

Mizuno set its robot up with an ST 200 driver and set it for a moderate ball speed of 155.08 mph. Next, they placed a sheet of urethane across the face to make it thicker, just to see what would happen.

“The reason we used urethane is there’s a urethane layer on carbon composite driver faces,” Voshall says. “It was only a millimeter thick but we saw ball speed go down.”

They next tried a sheet of nylon and, despite the added thickness, they saw ball speed go … up. Next, Mizuno tried a material it uses in its new baseball bats, a nylon-based polymer blend called Nanoalloy.

“We saw an even greater speed jump. It wasn’t massive – we’re talking from 155.08 to 155.35. But we saw added thickness and we saw the speed go up.

“Something dynamically different was happening between the face and the ball.”

In the baseball world, Mizuno is a bat company just like Mizuno Golf is a driver company. In other words, it’s not really a player. However, by adding Nanoalloy as a connector between the handle and the carbon barrel, Mizuno bats went from moderate performers to high performers. Ten of the top 25 homerun hitting teams in last year’s NCAA baseball tournament used Mizuno bats.

“People hear that the technology comes from our carbon bats and think it’s a carbon face but it’s not,” says Voshall. “It looks like carbon but it’s not carbon.”

“It’s Nanoalloy.”

Please read this next sentence carefully.

I know it looks like a carbon face but it is NOT a carbon face.

It’s not, it’s not, it’s not.

Now, spit three times, make the sign of the cross, eat a garlic clove and throw a pinch of salt over your left shoulder.

It’s not a carbon face.

It is a one-millimeter-thick layer epoxied to a normal titanium driver face. For what it’s worth, Mizuno is extremely confident about its durability.

Nanoalloy is a nylon material made by the Japanese materials company Toray. It’s also the answer to a question we posed when we visited Mizuno’s new fitting center in Atlanta called The Foundry. It was literally there on the wall for us.

Toray’s Nanoalloy is a proprietary polymer-based nanostructure. That means the polymers are mixed at the 100 to 200 nm – nanometer – level. A nanometer, as mentioned above, is one-billionth of a meter. The nanometer scale is used to measure atoms and molecules. For reference, a human hair is 80,000 to 100,000 nm wide and a DNA strand is 2 nm wide.

This minute mixing process gives Nanoalloy unique properties that ordinary polymers can’t achieve. The new Mizuno JPX One drivers feature a millimeter-thin layer of Nanoalloy adhered to a standard titanium face. If you were to tap it with your finger, it would feel firm and solid. When it impacts a golf ball at speed, however, it becomes significantly more elastic and more flexible.

“When you compress a titanium face at impact, you get some face deflection around the ball at the point of impact, plus some deflection on the crown,” says Voshall. “On the same impact with Nanoalloy on the face, there’s much more deflection in the impact zone, plus deflection on the face on either side of the impact, plus some deflection on the crown.”

Deflection, compression and ball speed

Wonky, I know, and you’re right to ask how this might generate more ball speed.

The same head is hitting the same ball at the same speed but with the Nanoalloy face, you see more deformation around the golf ball at the point of impact as well as all across the face.

Where is that deformation coming from?

“There’s only so much energy in this interaction,” says Voshall. “It’s the Nanoalloy layer that’s deforming and it’s actually taking deformation away from the golf ball. What that means is that energy loss in the golf ball is reduced.

“We’re making any ball play like a higher-compression golf ball.”

And the rule, as any good MyGolfSpy reader knows, is that higher compression equals more ball speed.

Firm, as the saying goes, is fast.

In the original robotic test, Mizuno placed a one-millimeter-thin Nanoalloy sheet over a standard driver face. The actual construction of the new JPX One drivers, while still a standard titanium face and body, is slightly different to accommodate the Nanoally face.

“What the Nanoalloy face is doing is stealing deflection from the ball and stealing a little deflection from the forged titanium face as well,” says Voshall.

What about CT and COR? Aren’t there limits?

Of course there are.

CT, or Characteristic Time, is the key USGA metric to corral ball speed. It measures in microseconds how long a ball can stay on a driver’s face at impact, which reflects relative face flex. The limit is 239 microseconds plus another 18 microseconds for manufacturing tolerances, which makes the practical limit 257 microseconds. CT is a faster and more mobile proxy for the now outmoded COR (coefficient of restitution) test. The COR limit is 0.830, meaning if you fire a ball at the center of a driver’s face at 100 mph, it can’t rebound at more than 83 mph.

COR is still on the books, but the real test is CT.

Wonky stuff, but here’s what’s important. First, the two aren’t connected linearly, meaning they don’t change in direct correlation to one another. Second, there are loopholes. Specifically, the USGA created a new rule to cover TaylorMade’s carbon face which included a urethane coating layer.

“Nanoalloy lives in the USGA’s world as a coating, even though it’s not a coating,” Voshall explains. “It’s a different material and a different layer. The USGA created a coating correction factor when TaylorMade went carbon. That created new opportunities for new loopholes and the possibility of more speed.”

Technically, the Mizuno JPX One drivers have a CT of around 220. However, Nanoalloy allows Mizuno to make its titanium faces up to 10 percent thinner without worrying about durability. A thinner face can get closer to the 0.830 COR limit over a wider area.

Additionally, shaving 10 percent off the heaviest part of the golf club gives MOI a huge boost. When that higher MOI is combined with a larger high COR area, more of the face is faster compared to a less-forgiving driver with a high center COR. A toe hit, for example, will be faster on a high MOI driver because there’s less torque at impact.

Enough wonk. What’s up with the drivers?

We told you this would be wonky but Mizuno doesn’t do catchphrase gimmickry. The wonk, we’re afraid, was necessary.

The new lineup features two drivers: the JPX One and JPX One Select. The JPX One is the “standard” model for the widest part of the bell curve while the still forgiving JPX One Select is aimed at better players.

Both are 460cc but the JPX One is a little shorter top to bottom, a little bigger front to back and a little wider heel to toe. The CG (center of gravity) is also a bit deeper.

The JPX One Select features a deeper face but is squattier front to back and heel to toe. It has the same tech, just a different geometry for a different player profile.

In Mizuno’s testing versus leading 2025 models, the company says the JPX One has the largest high COR area in its class, nearly 32 square millimeters bigger than the TaylorMade Qi35 MAX. The JPX One Select high COR area is only 14 square millimeters smaller than the Qi35 MAX but roughly 130 square millimeters larger than the Callaway Elyte Triple Diamond and the Titleist GT3.

Visually, the Mizuno JPX One drivers will remind you of the Titleist GT series, at least on the sole. The blue Nanoalloy face (IT’S NOT CARBON!) is distinctive but that’s what Mizuno was going for.

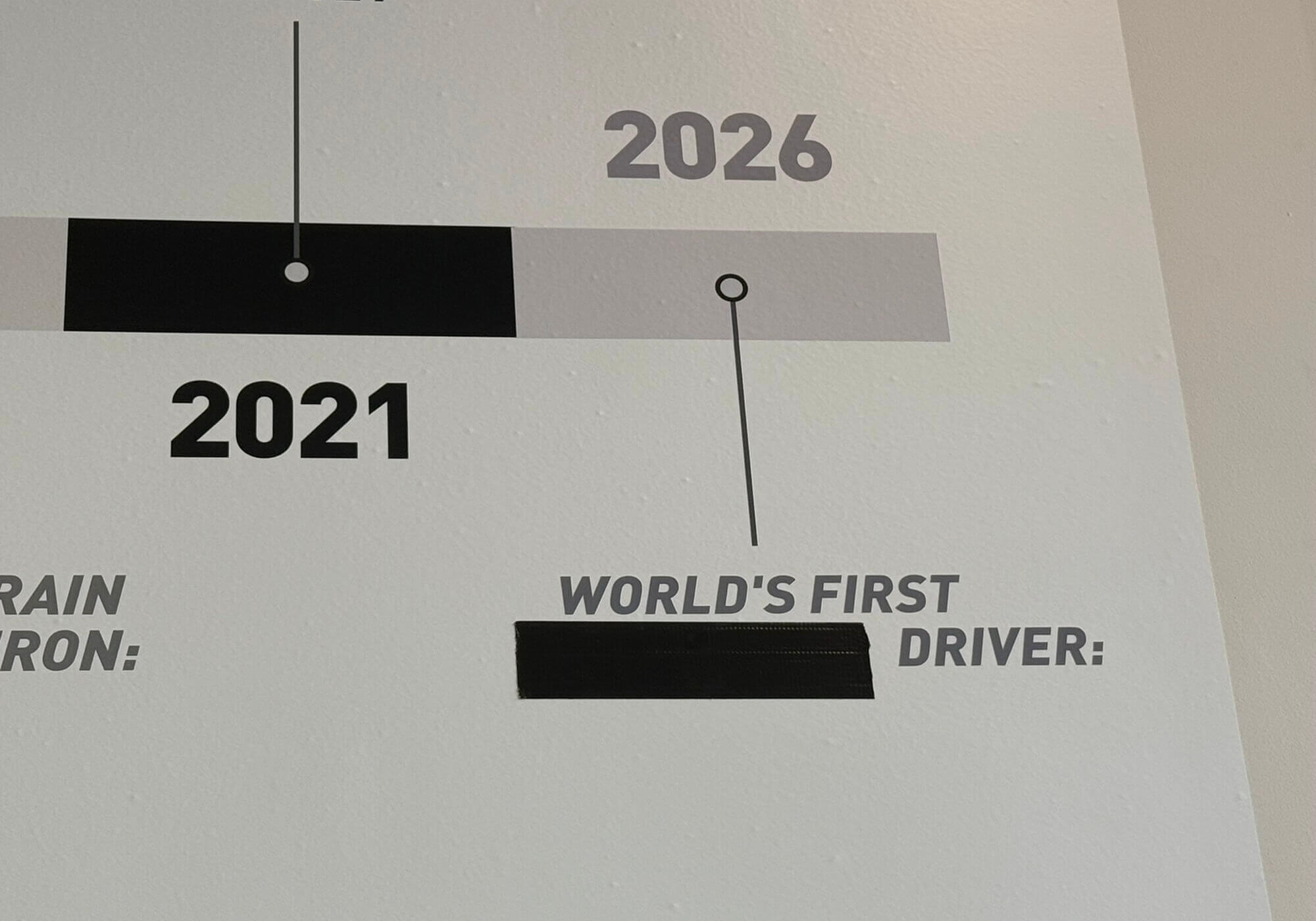

In final product testing (the original robot test was a Nanoalloy layer placed over an existing driver), Mizuno found ball speed gains of at least 0.7 mph. The company is conservative by nature, so your mileage may vary. If you bought a driver in 2025, that likely won’t prompt you to switch. But if you’re packing something from 2021 or earlier, the JPX One should definitely be on your demo list.

Mizuno JPX One and JPX One Select: Specs, price and availability

The Mizuno JPX One is the “standard” model and is available in nine-, 10.5- and 12-degree models (10.5 only for lefties). It’s loft-adjustable two degrees up or down.

The JPX One Select is considered the player’s model and is available in nine- and 10.5-degree lofts (the nine-degree model comes in LH). It’s also adjustable.

As usual, Mizuno is purposeful when selecting stock shafts. You can choose from the Mitsubishi Tensei 1K Black or 1K Blue as well as the Project X Denali Frost Blue.

The Tensei shafts use Mitsubishi’s 1K carbon fiber, thinner and more consistent than traditional carbon weaves. That gives the family a tight and stable signature feel. The 1K Black is low-launch/low-spin with a stiff tip and high kick point for more aggressive swings. The 1K Blue is mid/mid with a mid kick point. It’s considered more playable for a wider range of swing speeds.

The Denali Frost Blue is also mid-launch/mid-spin with a stable butt section designed for moderate tempos. It’s the same profile as the standard Denali Blue, just with a unique frosted blue cosmetic.

The UST Mamiya Helium NanoCore is also available. It’s an ultra-lightweight, high-launch/high-spin shaft for slower swing speeds.

A gray Golf Pride Tour Velvet Cord grip is standard.

Pricewise, $299 was a nice run, but those days are gone. Mizuno does not see itself as a “discount” brand in irons and it doesn’t want to be in drivers, either. The Mizuno JPX One and JPX One Select will retail for $599. That’s a big jump but it’s still below what other OEMs will be charging this year.

They’re available for presale starting January 12th. They hit the stores on January 22nd.

For more information, visit the Mizuno website.

The post Why You Need To Try The New – And Compelling – Mizuno JPX One Drivers appeared first on MyGolfSpy.